Clever technology helps the environment

AUTOMOTIVE TECHNOLOGY & ENVIRONMENTAL IMPACT

We combine new automotive technology and tools to provide the best possible service we can, and to reduce our impact on the environment.

We are proud to be using the following technology:

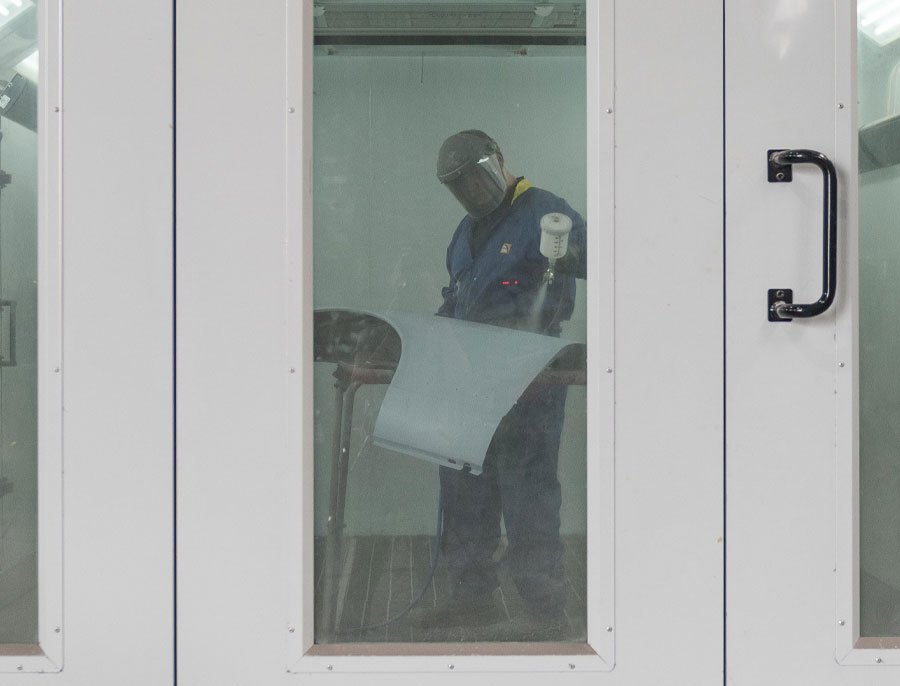

We have installed a CMC International fully down draft spray booth in our Traralgon Workshop. These booths are internationally known and recognised for their quality and technological advancement, which continues to be unsurpassed in the industry for manufacturing and installing world class units.

We have installed a CMC International fully down draft spray booth in our Traralgon Workshop. These booths are internationally known and recognised for their quality and technological advancement, which continues to be unsurpassed in the industry for manufacturing and installing world class units.

CMC’s customers include major corporations such as: Ferrari, Alfa Romeo, Fiat, Glassurit Technical Centre, British Aerospace, Air Bus, Torro Russo Red Bull, F1 Team.

Features of the spray both include:

- Spray booth with LED lights

- Long range infra red by nine elements (ECO Panels), with a tenth element in the air heating system

- Top corner lights with 4 flouros in each light fitting

- Antispark centrifugal fan on exhaust

- Vibration damper between cabin & fan

- Galvanized base & grills

- Low noise level

- Door rubbers with air cushion

- Compliance with all relevant standards

We have GONE GREEN and helped to save our environment by installing CMC ECO heating panels.

Advantages of using the ECO heating panels include:

- Economical and environmentally friendly

- No need for a burner

- No need for gas or diesel

- No need for submissions to local authorities

- Carbon monoxide free

- No need to heat up and exhaust large volumes of air, hence energy consumption is drastically reduced (approximately 80% lower)

- Electricity consumption for ventilation is drastically reduced

- Increases the life of filters

- Reduction in noise level

The manufacturer and supplier of the ECO panels has been established since 1978 and is a world leader in this type of industrial equipment.

To be compliant with government environmental regulations, we installed a Triple Interceptor as part of our new building.

Trade Waste is any wastewater that comes from a premises that is not a household. It is the liquid waste that is generated by an industry, business, trade or manufacturing process. This liquid waste has to be acceptable to be discharged into the sewerage system.

Before any Trade Waste can be discharged into the sewerage system, it needs to be pre-treated through an apparatus such as a grease or oil interceptor trap.

How does it work?

The triple interceptor tank design contains and slows the flow of waste to allow the grease, oils and traces of fuel and solvents to float and separate from the cleaner water which exits the tank from a low level.

All silts and sludge sink to the bottom.

As with all filtration systems, it needs to be cleaned too.

On a regular basis, the unit is emptied by a licensed contractor and the contents emptied in a controlled area as per EPA regulations.

Why do we need to manage Trade Waste?

- Protect the environment

- Reduce or eliminate odours

- Ensure effective waste treatment

- Allow waste water to be used after treatment

Using this innovative underground system is another way we avoid putting pollutants into the sewer network and support our environment.

We have a brand new Rotary Screw Compressor. The main advantage of this screw compressor is massive noise reduction compared to traditional air compressors. This makes a huge difference in our workshop and to our staff.

Other advantages:

- Maintenance is simple

- Less consumption of oil

- Shockless compression technology

- Nil reduction in capacity over a period of time

- 25 - 30 % higher energy efficiency than piston compressors

- A lot less vibration

- Due to the independent cooling fan and the coolant system, the outlet air is far cooler than the piston compressors

- The air quality produced by the screw compressor is far higher than the piston compressors

This is an essential tool to colour match your vehicle. See our colour matching page for more information on what this tool can do.

This is an essential tool to colour match your vehicle. See our colour matching page for more information on what this tool can do.

With modern cars and their computerised systems, the need for diagnostic tools is essential. Our Scan Tool is a computerised tool that reads any faults in your vehicle, so that we can diagnose any unseen issues. This is especially important for modern cars which contain a number of computers and airbag technology. You can have peace of mind that any issues will be reported to you and your insurance company and will be resolved at time of repair.

As development in automotive technology and extensive use of new materials increases, the technique in repairing a modern auto body has to keep up with the auto industry’s development.

The traditional auto body is made from soft or medium steel, but the modern auto body is made from hard steel which leads to greater differences in repairing.

Our CMC International Automotive Speed Bench enables us to pull a smashed vehicle in any direction using hydraulic power to realign it. Combined with our measuring system, this means that we can do small, medium and large smash repairs for a range of vehicles.

We use the latest cloud based software system called iBodyshop. This is an Australian designed and supplied software that is specifically designed for Panel Shops.

We use the latest cloud based software system called iBodyshop. This is an Australian designed and supplied software that is specifically designed for Panel Shops.

iBodyshop is a comprehensive and elaborate software suite that combines the complete repair process for all of our quoting, parts ordering, scheduling, employee management, invoicing, customer contact and so much more.

Additionally, it directly connects to the majority of Insurance Companies so we can upload our quote and photos for your car repair easily and simply.

In an ongoing effort to improve our technology and environmental impact, we have installed a 10KW Solar system at our Workshop.

Since the majority of our business is conducted in daylight hours, this should cover the majority of our electricity usage and is will reduce our environmental impact and running costs significantly.